8 popular forklifts & why you might need them

8 popular forklifts & why you might need them

Believe it or not, the history of the humble forklift dates back to the mid 1800s when countries such as the US and UK entered a gilded age of rapid economic growth. Factories and warehouses were expanding and as inventories and manufacturing operations grew, buildings were forced to expand and extend outward. However, as cities grew denser and production accelerated, both buildings and shelf heights had to adjust to a more practical method of storing and managing items.

The forerunners of the modern forklift were manually-powered hoists that were used to lift loads but by the early 1900’s the development of different types of material-handling equipment took off, from three wheeled battery powered platform trucks to powered lift tractors.

In 1917, the first version of the modern seated counterbalanced truck was developed. Known at the time as a "Tructractor"

Since then forklifts have made it possible to move more, faster and have become an indispensable piece of equipment, constantly evolving to keep up with the ever changing landscape of warehousing, manufacture and international supply chain.

If you run a warehouse, storage facility, or work on a construction site, a forklift is one of the most helpful and crucial pieces of equipment to invest in. However, like anything else, forklifts come in a range of varieties and styles. As a result, knowing what will best fit your needs might be challenging.

Whether you’re looking for a long term lease, to rent a forklift for your next project or purchase one for your business, our guide is a good starting point to help choose the right forklift for your needs.

Counterbalance forklift

The counterbalance fork truck is one of the most common forklifts used in indoor warehousing, outdoor yards and loading docs. This popular forklift does what it says on the tin with forks in the front and a weight in the back to counterbalance the weight of the load. This allows the machine to lift and move heavier loads than if the weight wasn’t there. Traditionally the use of diesel, petrol or LPG powered forklifts were the only choices but now there is a strong appetite for conventional lead-acid batteries or lithium-ion long-life batteries across all lifting ranges.

key features

- Back mounted weight that helps to balance loads.

- 3 and 4 wheeled options provide better maneuverability, making them a good for narrow isles

- Best for stable flat surfaces

- Fully enclosed cabs can be fitted for outside dusty or indoor temperature controlled environments

uses

- Often used for heavy operational purposes

- Areas where circle maneuvering is necessary

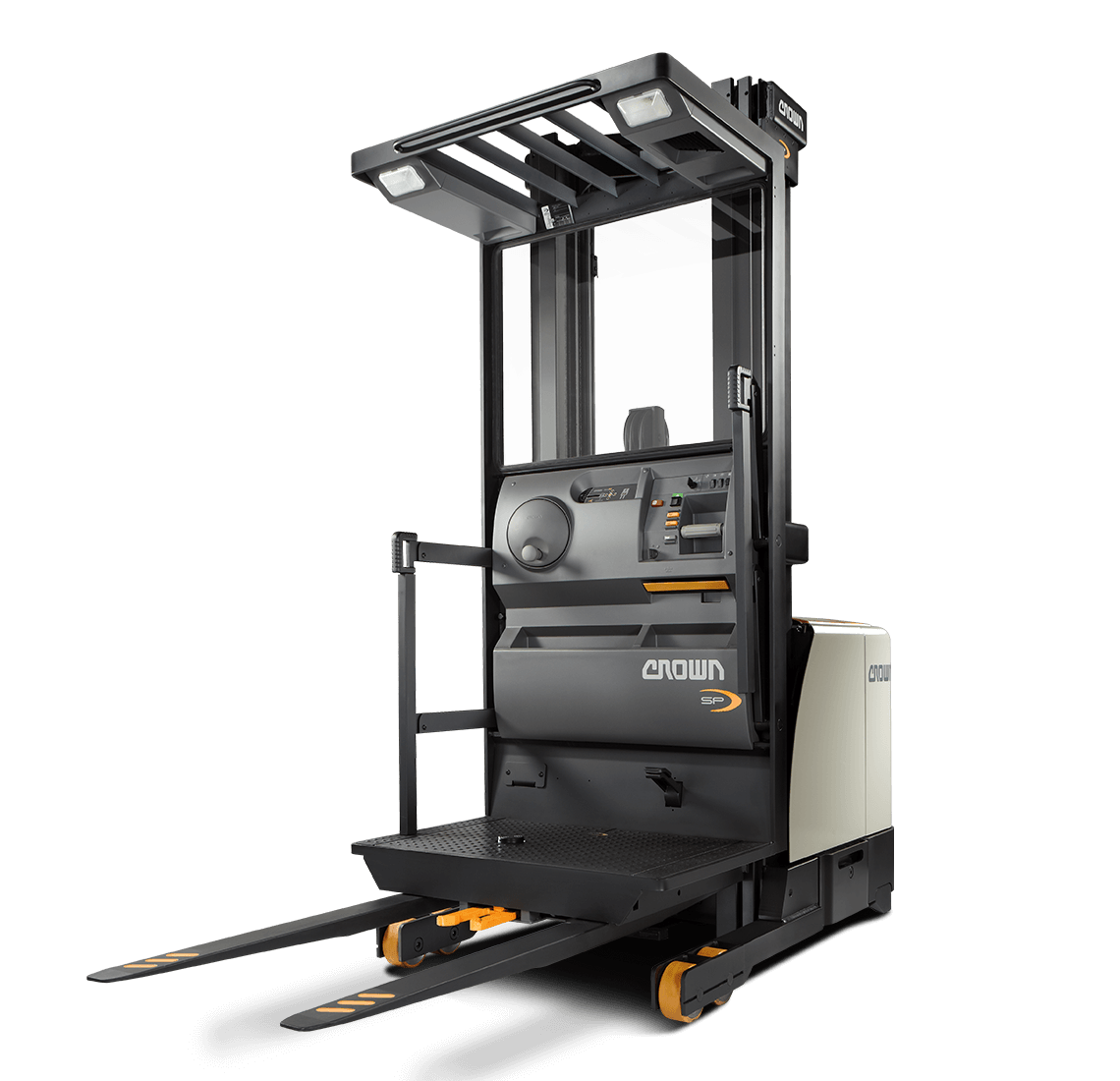

Warehouse forklift

A reach truck is normally smaller than a counter balance forklift allowing it to maneuver much more easily in a tight environment. Besides working in narrow spaces, including narrowing your aisles for more racking/pallet space, the other advantage of a reach truck is its lifting height and some makes/models can lift up as high as 15,000mm

Order pickers

Compared to the average forklift, order pickers and walkie stackers are very odd in their appearance. Generally used in customer order warehouses they are used to pick and deliver materials from storage. More specifically, for applications where only one or 2 units are needed, avoiding bringing down full pallets or loads. What they lack in power and speed they make up for in height, lifting operators up to warehouse racks anywhere up to 9,000mm to retrieve items.

Pallet jack

Another popular option for warehouse storage facilities is the pallet jack. Pedestrian operated, the forks at the front slide beneath the pallet to lift the load from the ground for easy maneuverability.

These forklifts aren’t capable of lifting heavier loads or raising them up to higher areas however they make up for it with their smaller footprint and portability allowing them to lift smaller loads in much more confined spaces.

Side loader forklift

Found in warehouses or yards where space is too tight to carry long loads on traditional counterbalance forklifts are the side loader. Whilst they may look like a ‘normal’ forklift, they have the ability to rotate their wheels by 90 degrees so that they can transport long or awkward loads without needing to clear a hug space to operate in. The two primary types of side loader forklifts are the enclosed cab, which is most often used for outdoors, and the stand-up variant, which is better suited to inside operations.

Rough terrain forklift

Up there as one of the largest in the forklift family, these robust forklifts were designed to be a heavy-duty lifting machine used on unpaved, uneven terrain. Generally, they have a more powerful engine so they have more torque (power) with better manoeuvrability, making them much more robust and durable.

Telehandler

Also knows as a telescopic handler, teleporter, boom lift, lull - the telehandler has a boom and extendable arm with forks making it the perfect mix of a forklift and a crane. A basic telehandler can have a lifting capacity of anything from 2 – 6 tons and 6,000-9,000mm in the air. Generally used as a ‘lift and place’ tool it can also be fitted with attachments such as buckets, lifting jibs, work platforms.

key features

- Extendable arm and articulating boom

- Can be fitted with other attachments for more versatile applications.

- Compact telehandlers can be used indoors in warehouses and manufacturing

uses

- Lifting loads off the ground to higher elevations

- Well suited to Agriculture and construction

- An alternative to the rough terrain forklift

- Often used in agriculture to move hay and hay bales.

Container Lifter

If you need to lift a shipping container, you can use a variety of machines for this application: Reach Stacker, Top Loader, Counterbalance, Straddle Carrier are the main machines. Your operating environment, will determine the best machine for the application whether it be for loading a truck or train, stacking containers, or moving multiple containers around for loading. These machines can lift 20’and 40’containers.

So, what is the best forklift for you? If you hadn’t already guessed there’s no simple answer but our team can help you find the right machine, for the right price to fit your needs.